About Maintenance and Balancing

Maintenance

El Alameya Group offers maintenance and servicing for all types of industrial fans (Axial fans or centrifugal fans) because industrial fans failure can have consequences beyond immediate financial and manufacturing losses.

Qualified engineers at our maintenance department offer fan refurbishment service. Recycling and reusing old fans, extending their life by manufacturing with the suitable materials, which is can be a cost-effective measure for businesses.

Balancing

The balancing of rotating bodies is important to avoid vibration. Dynamic and Static unbalancing in Heavy Industrial machinery such as generators and motors can cause catastrophic failure, as well as noise and discomfort. To help with balancing, it involves simply moving the center of gravity to the center of rotation. For systems to be completely balanced both the force and couple polygons should be closed.

El Alameya Group balancing department has three fixed static and dynamic balancing machines of the latest technology, of a capacity from 0.5kg to 20,000kg and balance according to ISO 1940.

PHW20000

The third balancing machine is the universal joint drive balancing machine PHW20000, its specification as follows:

- Special designed brackets can effectively transmit mechanical force

- The durable and reliable sensor possesses high sensitivity

- The permanent calibration brings high accuracy

- Driven by universal coupling transmit the power steadily

- Applicable to rotors which can’t be driven by belt or need large power

- Maximum weight of workpiece 20000 Kg

- Maximum shaft length up to 6 m.

- Maximum diameter of workpiece 3200 mm

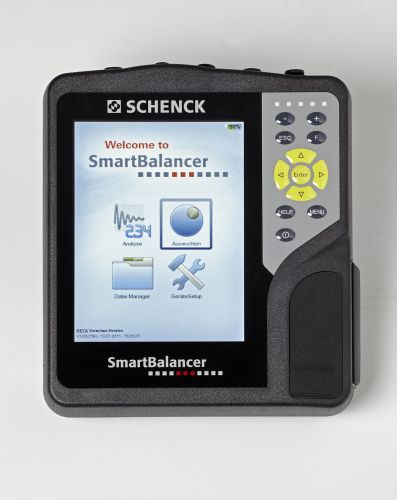

Smart Balancer

The Smart Balancer (SCHENCK, Made in Germany) is a handy instrument for balancing installed rotors fast, accurately and inexpensively without disassembling machines. You can correct rotors of practically any size or weight in one and two planes. It makes all of the important diagnostic options such as measuring overall vibrations, tracking analysis and FFT frequency analysis available. Its comprehensive equipment covers most of the other vibration measuring functions, making it a high-performance tool for machine diagnosis.

-

Smart balancer specifications as follows:

- No. of measurement channels: 2

- Balancing speed: 120 – 60.000 rpm

- Measurement functions: Field balancing Measurement of overall vibration Frequency analysis Run-up and run-down curves Vibration versus time Phase measurement